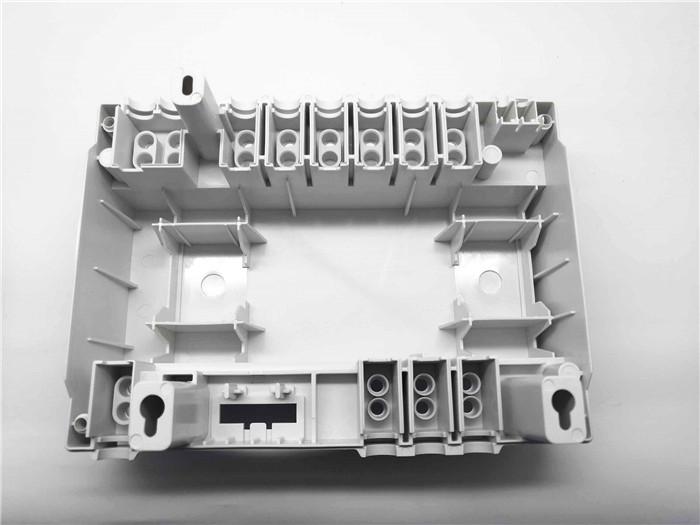

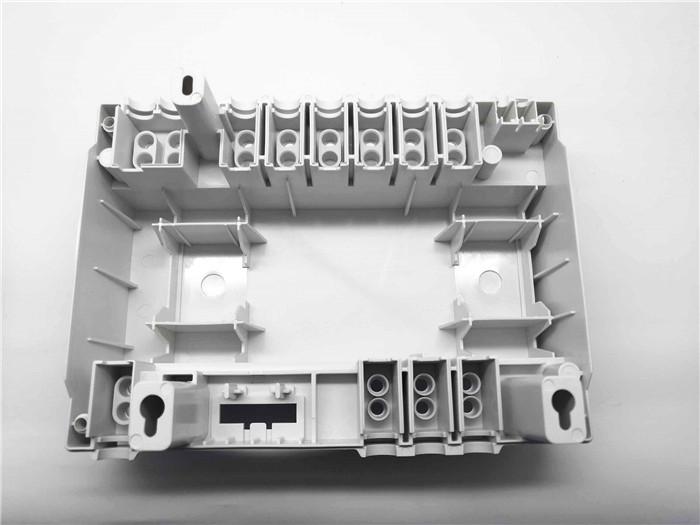

500000 Shots NAK80 S136 Nak80 Injection Molding Molds

Product Details Description

| Mould Type | 2/3 plate mold |

| Plastic Materials | H13, 2344, P20, 2311, Starvax 420, 236,S136, 2312, 2379, 2316,

2083, Nak80, 2767 ...etc. |

| Standard | DME/HASCO standard |

| Mould Base | Hasco Standard, European Standard, World Standard |

| Mould Base Material | S50C/P20 LKM, FUTA, HASCO, DME,...etc. Or as per Customer's

Requirment. |

| Quality system | RoSH and SGS standard |

| Feature | Non marking,non flash and non shrinkage |

| Package | Standard exported Wooden box packed, Fumigation process(upon

required) |

| Mold Building Lead Time | T1, 30-50 days after the mold 3D approved, depends on different

mold structure |

| Surface Finish | Texture(MT standard), High gloss polishing |

| Cavity/Core Steel | P20, 2311, H13, 2344, Starvax 420, 236,S136, 2312, 2379, 2316,

2083, Nak80, 2767 ...etc. |

| Cavity number | Single/multi cavity |

| Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow,

Mastip,...etc. |

| Mould Life | 1,000, 300,000 to 1,000,000 Shots. (According to your requirement.) |

| Design & Program Softwares | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

What we can offer:

1. Customized Making

- Per your drawings or samples, we can customize your mold.

- Per your requirement, we can modify and design your parts

structure to establish the overall 3D effect drawing. And per above

3D drawing, we can provide mold making quotation and product

molding quotation to you to help you to do the entire costing

analysis.

2. Prototype Making

We can make the prototype for you to help you understanding the

product detail and its outlooking (Ps. we will estimate the

prototype cost report to you from 3D printing or from NC milling

way).

3. Purchase Contract Making

If both of us agree to sign the contract, we will mention the

working detail, lead time, inspection standard, payment term

information…etc on the contract.

4. During the mold manufacturing period

- We will send the update working progress report each week with

photos.

- Before commencing making the mold and the machining process, if

customer needs to adjust the product’s shape slightly, we will not

charge the extra cost.

- If the machining process is on-going, and customer needs to

adjust the product design, we will study and give our report to see

whether we should charge extra cost or not.

- We will send T1, T2 or T3 samples till meeting customer`s

requirement.

5. Molding service

- After the final trial samples is approval by customer, if

customer places the product production to us, we will be

responsible for the mold maintenance and performance for all.

6. Packing and assembly

- For mold, we pack with standard exported wooden box with

fumigation process.

- For product, if there is no specific packing requirement, we will

use regular carton box and bag (free of charge). If customer

requires specific packing way.Meanhile, we can help customer to do

the assembly, packing and the printing from case to case.

7. Transportation

- Customers can use their own forwarder or we can help customer to

arrange any sea or air transportation forwarder to deliver the

goods to customer’s address.

Our Service

1. Engineering/ Technical

Mold design

Mold flow analysis

Project management

Supplier Managed Inventory

Design for Manufacturing

2. Mold Building

Mold up range from samll, middle and large

Complex Surfaces

Assembly Fixtures

Hot-Runner Capability

3. Technical Injection Molding

Structural Foam

Small Precision and Large Cosmetic

High Pressure Thin wall

Robotic and Automated Pick and Place

4. Plasting/die-casting molding

OUR ADVANTAGE

1. High precision equipment make process more efficient and

accurate

2. Sophisticated technology with good management

3. Experienced team specializes in molds and technical parts in

Complex geometries, exacting tolerances and the realization of

tools for fully automatic production

4. Certified by SGS, ROHS

5. Every work know how to check the product at his own stage, and

also can check the last step quality.

6. Inhouse CNC machining center, Sodick slow-feeding wire-cut,

Sodick mirror EDM, CMM etc

FAQ

Q1: Which is the safest payment method to trade?

A: We accept T/T, LC, Paypal, Trade Assurance and Secure Payment.

Q2: How can I get a sample for initial evaluation?

A: We can provide you samples for testing and evaluation

immediately upon your request.

Q3: Are you a manufactureror trading company?

A: We are a OEM/ODM company providing comprehensive product

development and manufacturing solutions.

Q4: What is the software you use for design and mold making?

A: We usually use UG, PROE, CAD, CAD/ProE/UG/SOLIDWORKS for mold 2D

and 3D design.

Q5: How you do the quality control?

A: we have system quality control process

1). Materials inspection by IQC;

2). The first sample inspected by QC, QC will do over check as per

the parameters list and critical dimensions requested by customers,

to decide if it can go ahead for production;

3). During processing, our IPQC will check the injection molded

parts every 2 hours, ensure no any rejects;

4). FQC will check the products before sending to the warehouse;

5). 100% inspected by OQC before shipping out.