Product Detials Desprition

| Plastic Material | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%,Rubber,

Silicone rubber, LSR,...etc. |

| Quality | ROSH and SGS standard |

| Mould Base | S50C HASCO standard, European standard, World standard |

| Mould Base Material | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

| Surface Finishing | Texture (MT standard), high gloss polishing |

| Cavity / Core material | P20, 2311, H13, 2344, Starvax 420, 236,AdC3, S136, 2312, 2379,

2316, 2083, Nak80, 2767 etc. |

| Cavity Number | Single cavity, Muti Cavity, based on customer’s requirement. |

| Hot / Cold Runner | HUSKY, INCOE, YUDO, HASCO, DME, MoldMaster, Masterflow, Mastip,etc. |

| Mould Life | 1,000 to 1,000,000 shots(according to your requirement) |

| Design & Program Softwares | CAD, CAM, CAE, Pro-E, Solid works…etc. |

| Package | Standard Artificial Wooden Box with Steel Frame |

| Mold building lead time | 30~50 days after mold 3D approved, mold manufacture process report,

mold trial report, parts measurement report (upon required). |

| Annual production | 30 set per month |

What kind of mold we can make?

1. Automotive mold

Automotive trim, Rearview mirror shell,Central glive box,Front and

rear wheel brow,Door frame,Roof rack,Before and after the retaining

bar

Round shel cover plate,front and rear pedal,Air outlet grille, Auto

lamp,The front baffle,Cockpit,Plastic Spindle

2. Home appliance product mold

Kitchen Appliances,Coffee port cover,Baby Plastic Tray Covers,Home

appliance component,Plastic Spoon,Plastic Filter Shim, Home

appliance component,Bottle Cap

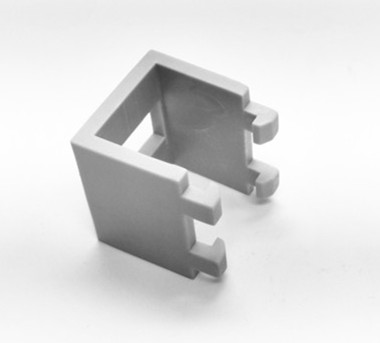

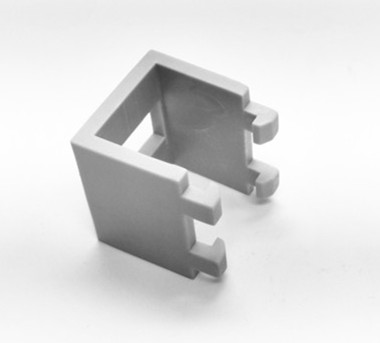

3. Electronic product mold

Digital Signal Processor Cover,Plastic Lampholder,Plastic Lamp

Shade,Socket Cover, Enclosure Cover,Semi-transparent Lamp

Shade,Electronic Product Shell,Heating Panel,Intelligent

Touch-screen Cover and Base

4. Over-mould injection mold

Bi-color cap, remote control mold, Hand Grip/hold/knob/shank,Road

Traffic Cones Base,Cosmetic Bi Color Fliptop Cap,Bi-color Screen

Frame,Medical product hand Grip

5. Medical injection mold

Rapid Cap for Insulin Pen,Sleep Posture Belt,Len Case,Dental deill

cover,Orthotic foot cushions,Artificial nipples

6. Industrial product mold

Insert molding,Plug Lid,Plastic Belt Buckle, plastis base

cover,Vacuum Cleaner Connection, Rail Connection,Traffice Guidepost

Cap, Plunger Guide Cap,Instrument Frame,Plastic Leg,Machine support

insert,Connection Box,Industrial Container

7. Die casting mold

Camera Chassis,Radio Assembly for Satellite Systems,Camera

Housing,Cartridge Adhesive Applicators,Tablet Frame,toothbrush base

and shaft, heat sink for LED headlinghts, phone front

cover,Aluminum Heat Sink Cover,Aluminum Motor Cover

Quality Assurance is the key to success for KYE Moulds,

high-quality/defect free products is the reason KYE enjoys repeat

business from our list of satisfied customers.We use high precision

measurement tools and advanced video devices to check all parts and

processes from incoming material till outgoing final inspection, to

ensure only qualified products will be sent out to our customers.

Quality Control System

It`s a long process for each product from material purchasing to

the final delivery. If an error can not be identified timely, the

delivery will get delay, and cause waste on human labor and

material etc. To ensure customer get the qualify products,

Cents QC Procedure

1. Part mold draft analysis

2. Mold design control

3. Steel hardness inspection

4. Dimension inspection of electrode ,cavity and core

5. Mold trial report and inspection report

6. PPAP

7. Shipment inspection

FAQ

Q: What is your monthly capacity of mold making?

Our capability is 30 sets-50 sets molds one month,however, it

depends of different products.

Q. What's your mold tolerance?

A. 0.005-0.02mm according to different product requirements.

Q. What I should offer to you if I need a quote?

A. 2D product drawing & 3D File, or send us real plastic sample.

Q. Which material will your factory use to make a mold?

A. Our regular material has NAK80, S136, LKM, DAIDO, HASCO, DME

Q. What's your delivery time for molds and plastic injection

products?

A. Our delivery time for mold: 3-5 weeks as mold structure

complexity.

Plastic injection products: 3-18 days.

Q. What we need to provide if we want to start cooperation?

A. 1. 3D file or Real sample for your products;

2. Material you require;

3. Surface treatment requirement